In touch with tomorrow.

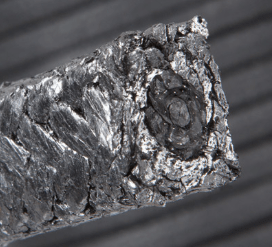

Due to the nature of the construction of this packing, it will not burn, blaze or fail due to loss of lubrication.

The excellent heat transfer capabilities of the carbon yarn, along with the lubricant used, makes K466M ideal for high temperature and pressure applications.

| Temperature Range | -240°C - 430°C -650°C - Steam |

| Pressure Range | 0 - 115 Bar** |

| Sliding Velocity | 20 m/s |

| pH Range | 0 - 14 |

K3222 can be used on all clean service centrifugal type pumps and valves. It is widely used in the petrochemical, pulp and paper and power generation industries.

Do not use this packing in applications with chromium trioxide, nitric acid and sulphuric acid.

| Temperature Range | -200°C - 430°C |

| Pressure Range | 0 - 180 Bar** |

| Sliding Velocity | 20 m/s |

| pH Range | 0 - 14 |

Static/door seals in steam boilers, reformers, furnaces, kilns, brick car damper seals, radiant tube packing for heat treat furnaces, thermocouple tubes in heat exchangers, insulation of pipelines, exhausts and pipeline expansion joints.

| Temperature Range | 0°C - 700°C |

| Pressure Range | 0 - 5 Bar |

| Sliding Velocity | 0 m/s |

| pH Range | 3 - 9 |

| Temperature Range |

Oxidizing: 0°C - 430°C Non Oxidizing: 0°C - 2760°C |

| Pressure Range | 0 - 840 Bar |

| Sliding Velocity | 0 m/s |

| pH Range | 1 - 14 |

| Temperature Range | Oxidizing: 0°C - 430°C Non Oxidizing: 0°C - 2760°C |

| Pressure Range | 0 - 360 Bar |

| Sliding Velocity | 20 m/s |

| pH Range | 1 - 14 |

| Temperature Range | -150°C - 430°C |

| Pressure Range | 0 - 45 Bar* |

| Sliding Velocity | 20 m/s |

| pH Range | 0 - 14 |

K35 Die-Formed Rings offer a leak free sealing solution for high performance valve applications which require excellent pressure and temperature

characteristics.

The manufacturing process ensures a product that is volumetrically stable – without fillers or binders. K35 rings are also essentially impermeable and without porosity.

KLINGER can manufacture virtually any size, section or density of die-formed ring. Required information:

| Temperature Range | General: -240°C - 430°C Steam applications: -240°C - 430°C |

| Pressure Range | Static: 350 Bar Dynamic: 20 Bar |

| Sliding Velocity | 5 m/s |

| pH Range | 0 - 14 |

*Maximum values – temperature, pH and speed should not be combined in any one application without careful consideration.

**Static applications – pressure range may vary depending on sliding velocity and shaft action.

Contact your local sales representative or our Gland Packing Product Specialist for further information and expert advice.

KLINGER has been the world’s leading manufacturer and provider of industrial sealing, fluid control and fluid monitoring systems for more than 130 years.

KLINGER Mzansi (Pty) Ltd | KLINGER (Pty) Ltd | KLINGER Zambia Ltd