Tailored to your needs.

- Home

- |

- Products

- |

- Fluid Sealing

- |

- Expansion Joints, Bellows & Metal Hoses

OUR RANGE OF EXPANSION JOINTS, BELLOWS AND METAL HOSES

KLINGER offers a wide range of high-quality, custom-designed, expansion joints, bellows and metal hoses for any application.

Understanding the diverse requirements of operators around the world, the offering includes standard designs as well as products specifically tailored to meet customer and industry-specific requirements. Furthermore, the entire range is designed and manufactured in-house, thus ensuring the high quality and reliability of the expansion joints, bellows and metal hoses on offer.

Expansion Joints

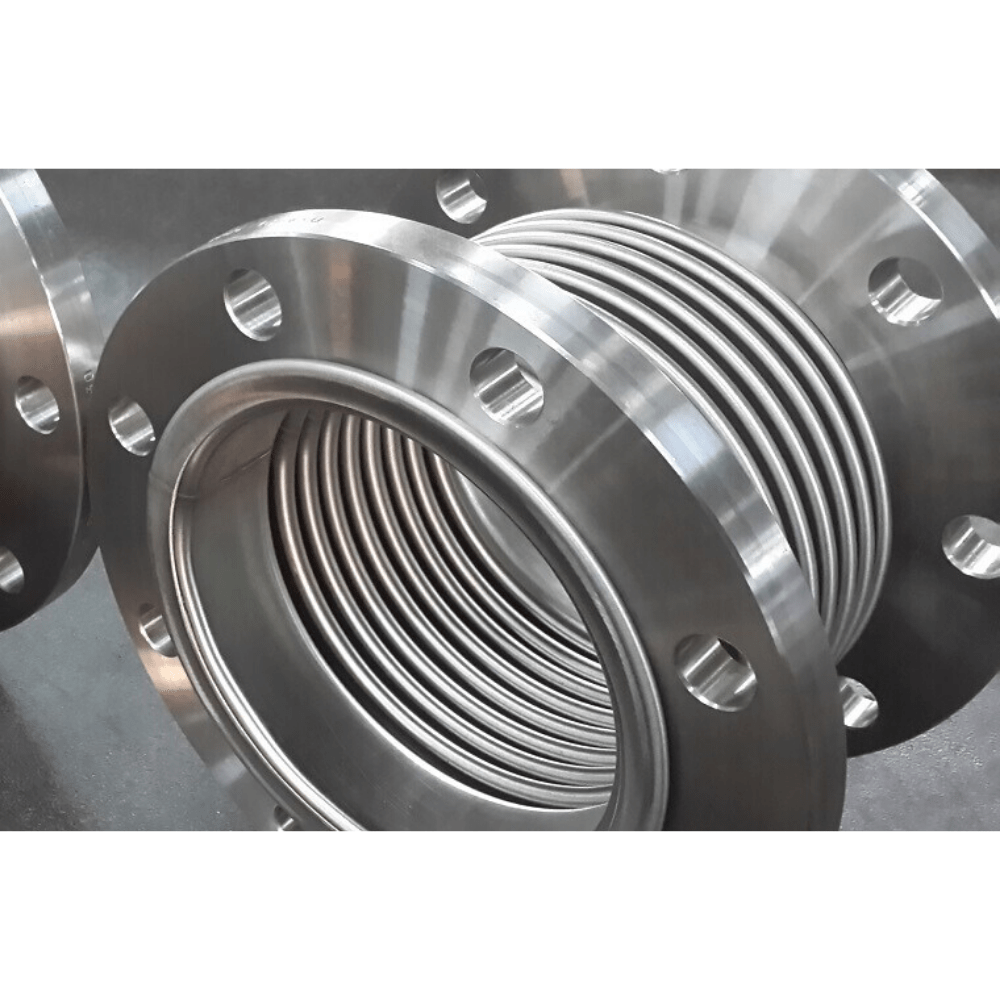

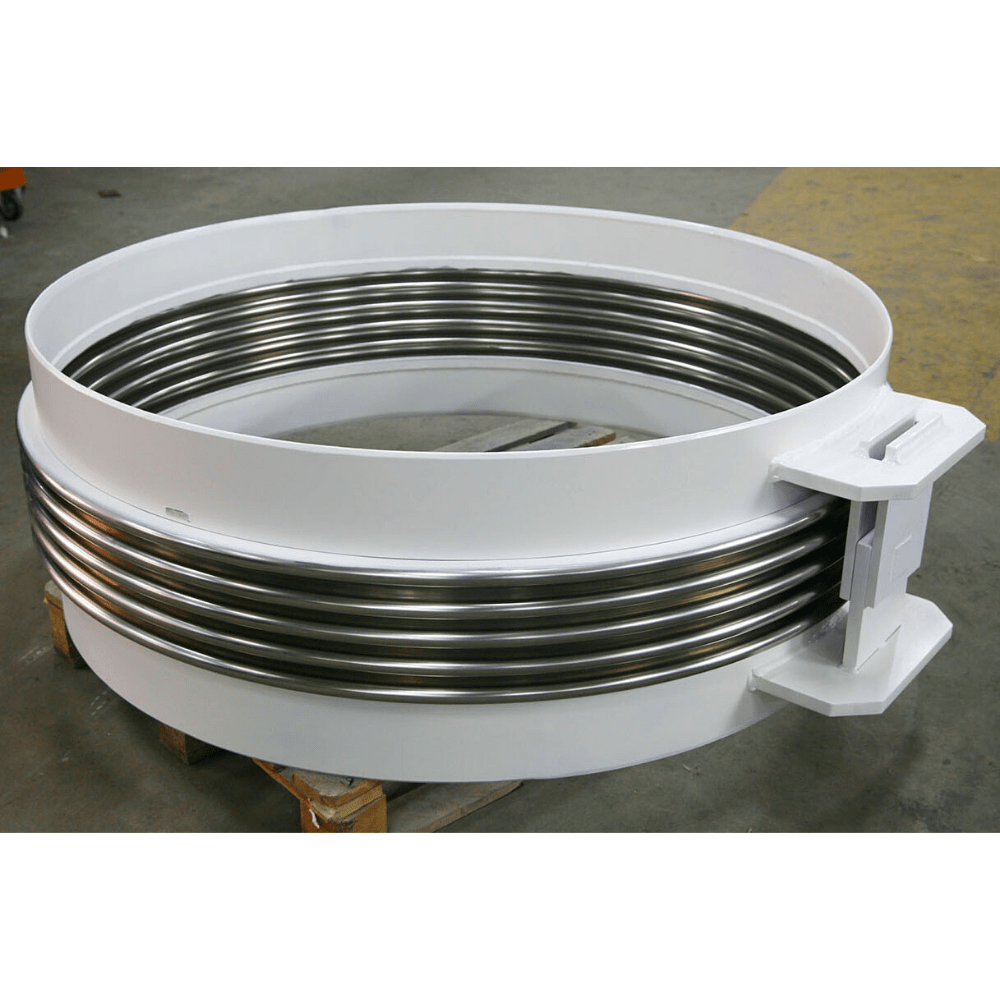

Expansion joints contain either one or multiple flexible elements to compensate for dimensional changes, which may be caused by thermal expansion or contraction of a pipeline, duct or vessel. Bellows type expansion joints, a “specialty” of KLINGER, are characterized by being virtually maintenance-free. KLINGER’s expansion joints represent a highly specialized product offering, which requires the customer to state the diameter, design movements, pressure and temperature, materials of construction, connection type and length in order to receive the expansion joint tailored to his specific needs.

Most metals expand as temperature rises and contract when it decreases. In pipelines this causes variation in the length of individual sections of the pipeline. As pipelines are normally anchored from at least two connection points, any variation in length causes thermal strain in the material and enhanced forces at the connection points. Pipe expansion is as far as possible compensated with the natural flexibility of the pipeline, but should this be insufficient, expansion joints are needed to compensate for the movements.

In addition, expansion joints absorb mechanical vibrations of pumps, compressors, turbines and engines, which could otherwise cause damage to the adjoining pipelines, their supports or any other installed instruments.

Central component in expansion joints is the bellow, which thanks to its shape and thin wall acts like a spring. In order for the bellow to be suitable for use as an expansion element, however, it must meet the following criteria:

- The bellow must withstand the pipeline’s operating and testing conditions

- The bellow has to ensure corrosion resistance against both inner and outer conditions of the pipeline

- The bellow needs to be flexible enough to compensate for the thermal expansion and mechanical vibrations with the durability requested from it

- The bellow must include sufficient squirm stability

Types

- Metal Expansion Joints

- Rubber Expansion Joints

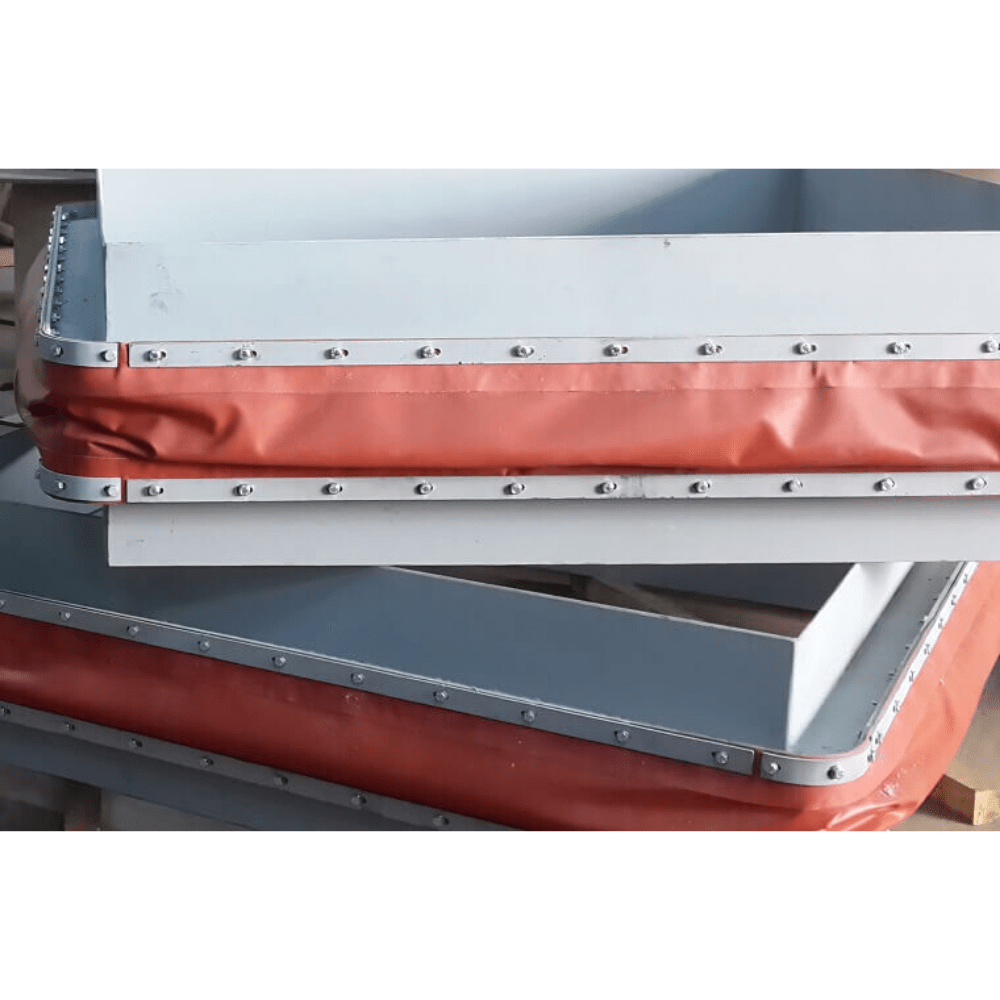

- Fabric Expansion Joints

- PTFE Expansion Joints

Bellows

Our range of bellows includes two different types: edge welded and formed. Formed bellows are manufactured from a thin-walled cylindrical metal tube, which is formed into corrugations using hydraulic or mechanical pressure. Edge welded bellows, on the other hand, are manufactured from individual metal diaphragms that are welded together.

Regardless of the way of manufacturing, the bellows in our product range are extremely flexible and durable. Bellows are resistant to pressure and temperature, and are vacuum-tight.

Bellows are typically used as:

- Shaft seals of valves

- Vibration absorbers in laser systems

- Volume compensators in transformers

- Actuators in measurement and control applications

- Flexible connection between solar panels

- Sealing or ducting elements in vacuum applications

- Temperature sensors

- Reservoirs to store fluids

- Pressure sensors

Metal Hoses

KLINGER’s product range of metal hoses are indispensable in applications where movement or thermal expansion causes tension and fatigue to a pipeline. Utilizing metal hose solutions counters the formation of pipeline cracks or leakages.

Metal hoses offer a solution to applications, where vibration, movement or thermal expansion cause tension and fatigue to the pipeline. Metal hoses can counteract misalignment and thermal expansion, as well as minimize the movement caused by vibration and machine operation. The use of metal hoses prevents cracks or leakages forming in the pipeline.

We supply metal hoses both according to standard measurements and according to the customer’s own measurements.

Types

- Flexible braided as well as unbraided metal hoses

- Boiler hoses

- Heat exchanger coils

- Hoses specifically designed for solar applications

- HT Composite pre-insulated hoses

- Hoses specifically designed for district heating applications