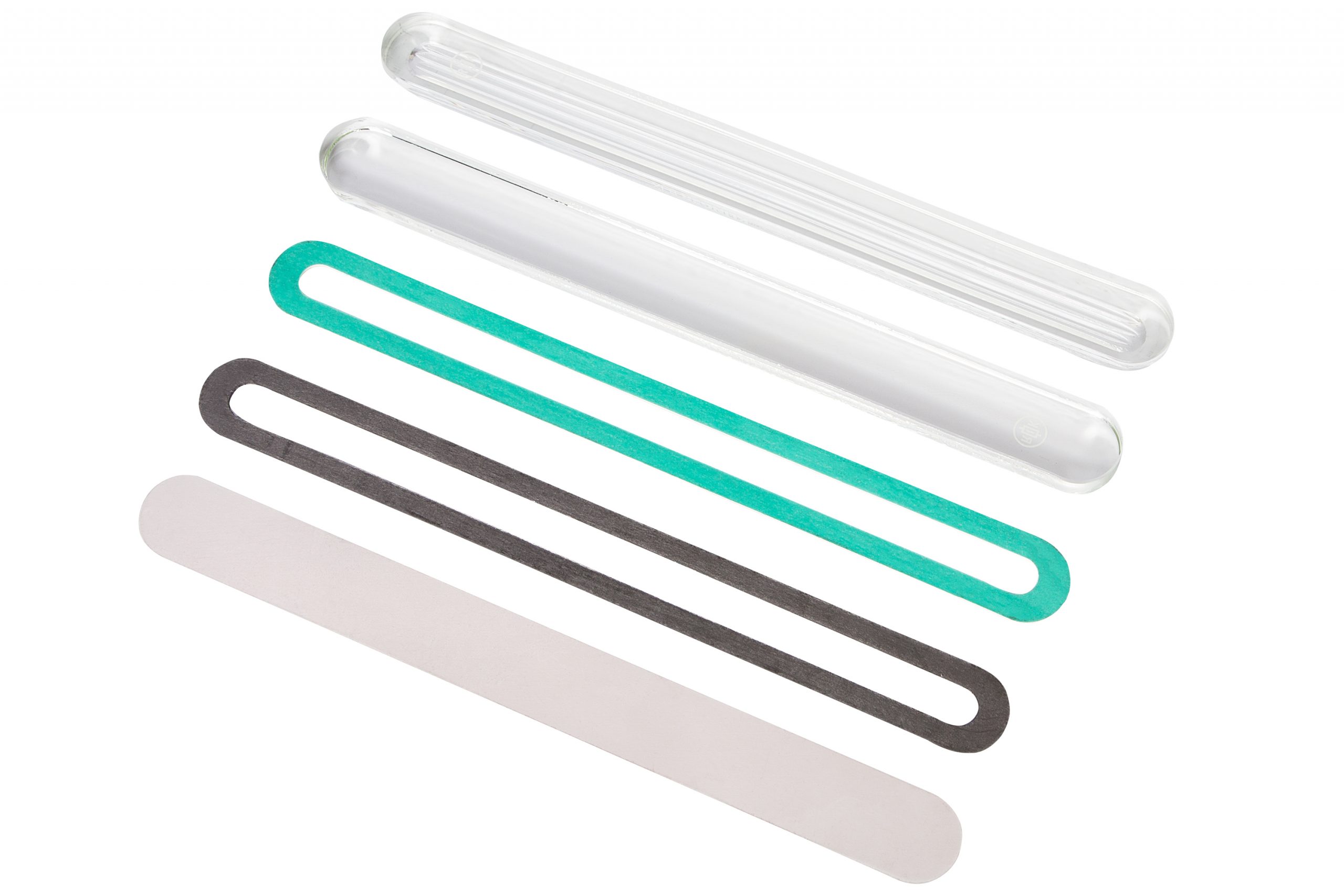

Transparent

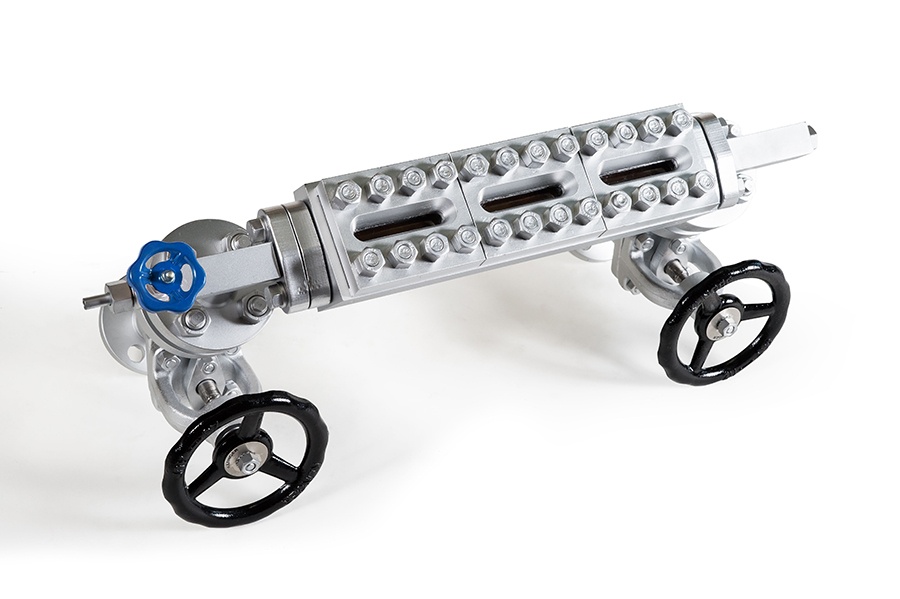

The medium is contained within two glasses whose surfaces are both smooth. Pressure rating: Up to 250 bar process or up to 120 bar steam. Materials: Forged steel or stainless steel. Tank connections: Screwed, flanged or butt-weld.

Sizes: Up to 3000mm centre to centre